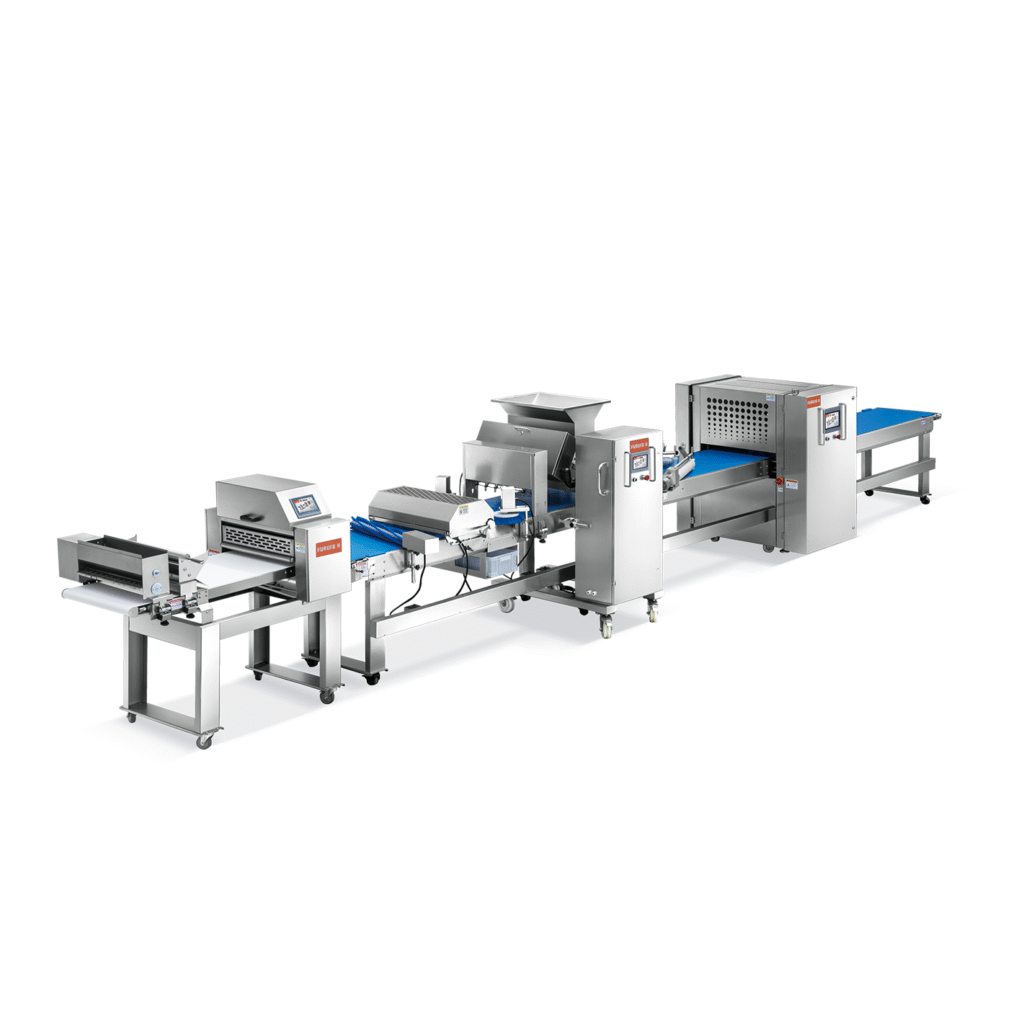

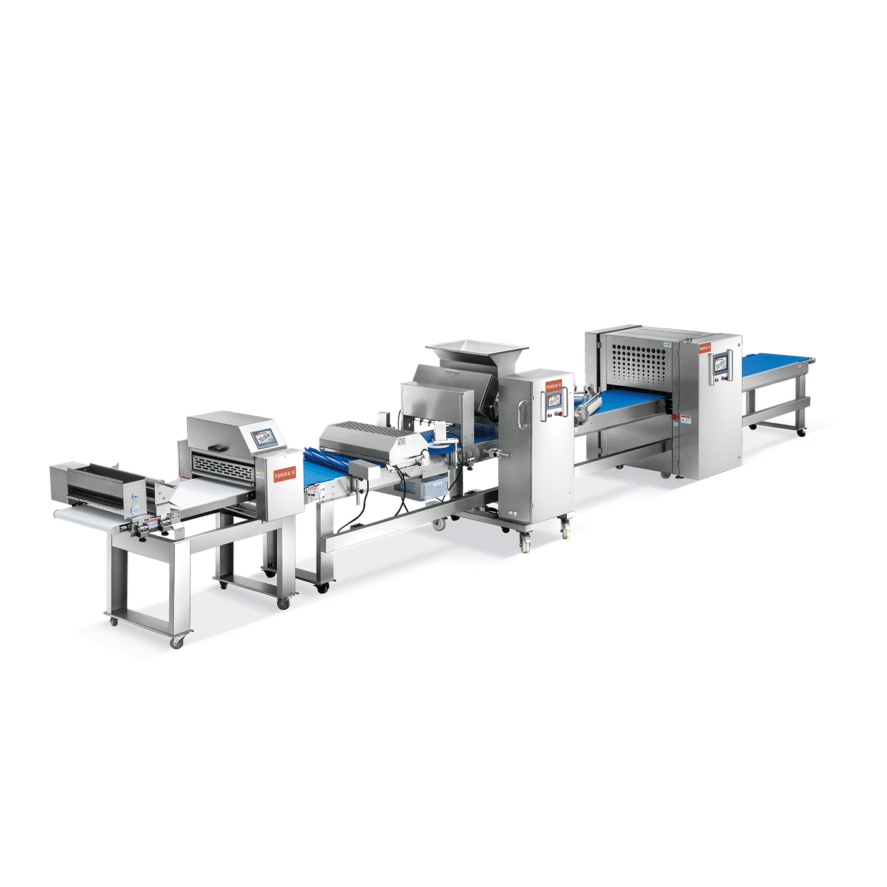

FR-DM800 Ligne de maquillage à haute performance

FR-DM800-High-Performance-Pastry-Make-Up-Line

Penser aux machines et équipements de boulangerie? Pensez à l'autoroute! Nous sommes développeur et fabricant d'outils, Machines et lignes pour les produits de cuisson polyvalente tels que les croissants, pain, Pâtisseries danoises, taco, pizza, Donut, biscuits et bretzels.

Convient aux boulangeries, restaurants, hôtels, et autre entreprise de services alimentaires. La ligne de maquillage FR-DM800 de Freeway est un système flexible et multifonctionnel qui peut fabriquer une large gamme de produits tels que les croissants, rouleaux de saucisse, Pâtisseries danoises, et plus de pâtisseries remplies de crème. Équipé de servomoteurs, caractéristiques de sécurité, Ordinateur micro-emballé, et panneau de touche LCD, Cette ligne augmente la production et l'efficacité de votre boulangerie. Sûr à utiliser et facile à nettoyer.

Toute la ligne se compose de 7 modules: 1. Tête d'étalonnage, 2. Unité de gaufrage et d'écran, 3. Remplissage, 4. Rouleaux enroulés, 5. Outils de guillotine et de poinçonnage, 6. Charrues pliantes, 7. Unité de commande de ligne.

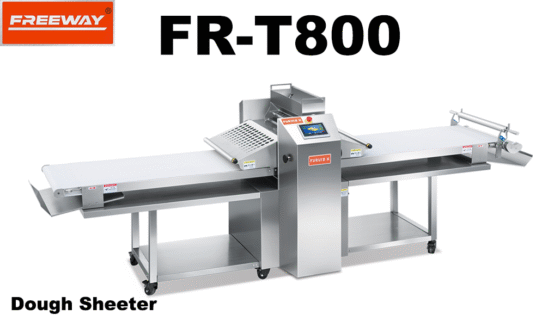

je. Tête d'étalonnage

Lorsque vous nourrissez la ligne avec une bobine de pâte, La tête d'étalonnage fait l'épaisseur et le poids de la pâte (Surtout pendant la transition) être uniformément distribué. Le contrôle de la boucle de pâte garantit que le drap de pâte passe à travers la tête d'étalonnage sans tension ni étirement (dans l'alimentation avec une échelle de pâte électromagnétique et à la sortie avec capteur de lumière).

- Traitement continu sans interruption

- Épaisseur de tôle de pâte uniforme (surtout aux extrémités qui se chevauchent)

- Tension et traitement sans étirement en raison du système de contrôle de la boucle de pâte

Ii. Unité de gaufrage et d'écran

Unité de gaufrage et d'écran

III. Remplissage

L'unité de remplissage peut remplir la pâte d'uniformité et de précision, Sans interruption. Nous fournissons des solutions différentes pour les garnitures dans différentes conditions telles que le liquide, crémeux, épais, ou thready sous leurs formes. Il y a des rouleaux d'admission à l'intérieur de l'unité de remplissage qui sont utilisés pour le remplissage des questions avec une flux limité. D'autre part, Les garnitures contenant des pièces de fruits sont appliquées doucement avec un système d'application de particules solides en amont. Une grande variété de buses de remplissage et de systèmes d'application satisfait à toutes les exigences possibles. Le nombre de lignes de remplissage peut être ajusté de manière flexible au nombre de lignes de produit en raison de pistons détachables individuellement. Bien sûr, Toutes nos unités de remplissage peuvent également être lavées.

- Dosage précis et positionnement de la garniture

- Remplissage de quantité infiniment réglable

- Nettoyage rapide et facile

Iv. Rouleaux enroulés

Les rouleaux enroulés permettent l'automatisation, Production précise de tourbillons danois et de produits similaires. Ils enroulent la tôle de pâte avec la matière de remplissage soit unilatéral (avec un rouleau) ou bilatéral (avec deux rouleaux). En même temps, Ils sont faciles à monter et à nettoyer.

V. Outils de guillotine et de poinçonnage

Le coupeur à moteur servo fonctionne en douceur et tranche avec précision avec un contrôle électronique de la longueur de coupe. Il réalise une performance de Max. 90 coups / min lors de la coupe croisée (opération continue) et max. 20 coups / min lors du coup de poing. Il est facile et rapide de remplacer divers coupeurs et outils à l'aide du système à changement rapide et de l'aide de positionnement.

- Coupure précise et coup de poing

- Haute capacité et flexibilité

- Temps de transition courts

VI. Charrues pliantes

Fiable, Les charrues pliantes individualisées facilitent considérablement la production automatisée de différentes pâtisseries. S'ils sont simples, collecteur, ou des plis alternés - il y a toujours une solution appropriée indépendamment des caractéristiques et des caractéristiques de la pâte de vos produits

Vii. Unité de commande de ligne

L'unité de commande de ligne est composée d'un ordinateur micro-industriel à l'intérieur et d'un panneau tactile LCD sur la surface métallique. GUI convivial et concise (Interface utilisateur graphique) joue un rôle important dans la surveillance, Réglage et interaction avec la ligne. C'est pourquoi nous avons développé le système d'exploitation intégré spécifique qui peut recevoir des paramètres de production (vitesse, longueur de coupe, type de remplissage et décalage de remplissage, mode de fonctionnement, etc.) entré par les utilisateurs du panneau LCD Touch. L'ensemble du processus de production est sous le toucher de vos doigts. Tous les lecteurs de ceinture peuvent être ajustés en continu via le panneau tactile LCD. Donc, Leur vitesse peut être contrôlée uniformément et uniformément avec un contrôle central du pilote tout au long du processus.

- Running simple et direct de la ligne

- Moniteur clair du processus de production

- Améliorer les performances de la ligne, robustesse, et stabilité

autoroute

autoroute

WeChat

Scannez le QR Code avec WeChat