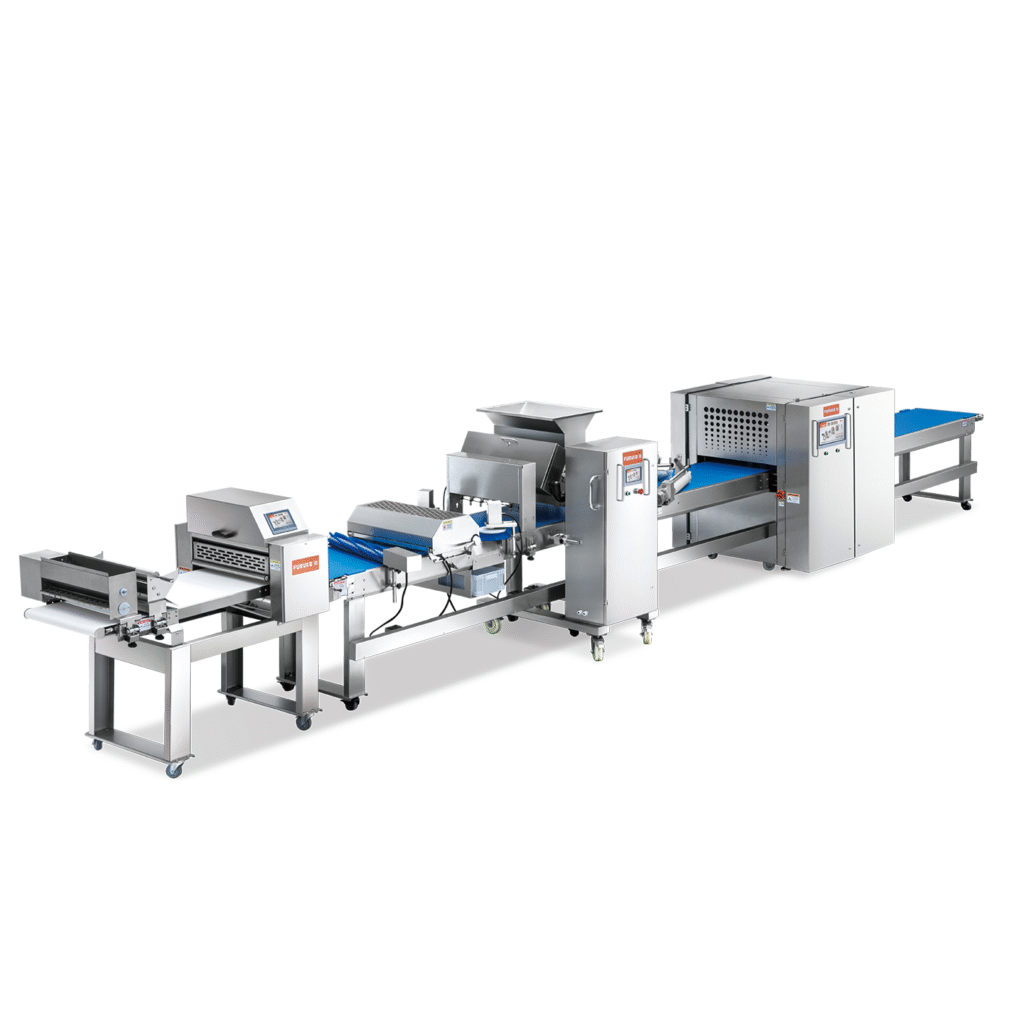

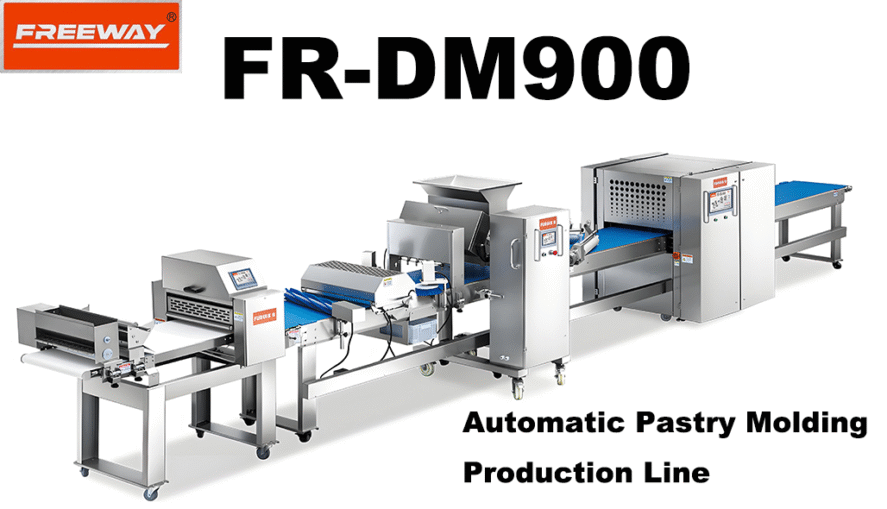

FR-DM900 Ligne de production de pâtisserie très efficace

FR-DM900 Ligne de production de pâtisserie très efficace

Penser aux machines et équipements de boulangerie? Pensez à l'autoroute!

Convient aux boulangeries, restaurants, hôtels, et autre entreprise de services alimentaires. La ligne de maquillage FR-DM900 de Freeway est conçue pour des performances optimales. Équipé de caractéristiques de sécurité, Contrôles d'épaisseur de rouleaux prédéfinis, et des tables pliables pour le stockage d'économie d'espace, Cette ligne augmente la production et l'efficacité de votre boulangerie. Sûr à utiliser et facile à nettoyer.

Toute la ligne se compose de 7 modules: 1. Tête d'étalonnage, 2. Unité de gaufrage et d'écran, 3. Remplissage, 4. Rouleaux enroulés, 5. Outils de guillotine et de poinçonnage, 6. Charrues pliantes, 7. Unité de commande de ligne.

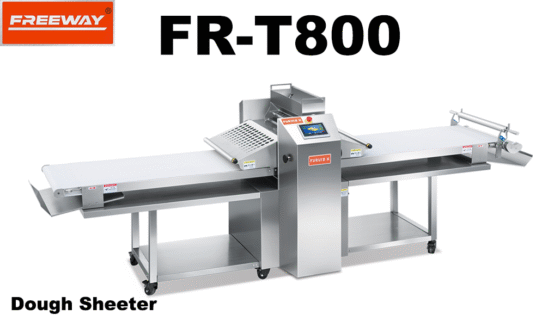

je. Tête d'étalonnage

Lorsque vous nourrissez la ligne avec une bobine de pâte, La tête d'étalonnage fait l'épaisseur et le poids de la pâte (Surtout pendant la transition) être uniformément distribué. Le contrôle de la boucle de pâte garantit que le drap de pâte passe à travers la tête d'étalonnage sans tension ni étirement (dans l'alimentation avec une échelle de pâte électromagnétique et à la sortie avec capteur photoélectrique).

- Traitement continu sans interruption

Ii. Unité de gaufrage et d'écran

Unité de gaufrage et d'écran

III. Remplissage

L'unité de remplissage peut remplir la pâte d'uniformité et de précision, sans interruption..

- Dosage précis et positionnement de la garniture

- La quantité de remplissage est réglable

- Nettoyage rapide et facile

Iv. Rouleaux enroulés

Les rouleaux enroulés permettent l'automatisation, Production précise de tourbillons danois et de produits similaires.

V. Outils de guillotine et de poinçonnage

La guillotine à moteur servo fonctionne en douceur et tranche avec précision avec un contrôle électronique de la longueur de coupe. Il réalise une performance de Max. Il est facile et rapide de remplacer diverses lames et outils à l'aide du système à changement rapide et de l'aide de positionnement.

- Coupure précise et coup de poing

- Haute capacité et flexibilité

- Temps de transition court dans le remplacement des outils

VI. Charrues pliantes

Fiable, Les charrues pliantes individualisées facilitent considérablement la production automatisée de différentes pâtisseries.

Vii. Unité de commande de ligne

L'unité de commande de ligne est composée d'un ordinateur micro-industriel à l'intérieur et d'un panneau tactile LCD sur la surface métallique. GUI convivial et concise (Interface utilisateur graphique) joue un rôle important dans la surveillance, Réglage et interaction avec la ligne. C'est pourquoi nous avons développé le système d'exploitation intégré spécifique qui peut recevoir des paramètres de production (vitesse, longueur de coupe, type de remplissage et décalage de remplissage, mode de fonctionnement, etc.) entré par les utilisateurs du panneau LCD Touch. L'ensemble du processus de production est sous le toucher de vos doigts. Tous les lecteurs de ceinture peuvent être ajustés en continu via le panneau tactile LCD.

- Running simple et direct de la ligne

- Moniteur clair du processus de production

- Améliorer les performances de la ligne, robustesse, et stabilité1

autoroute

autoroute

WeChat

Scannez le QR Code avec WeChat