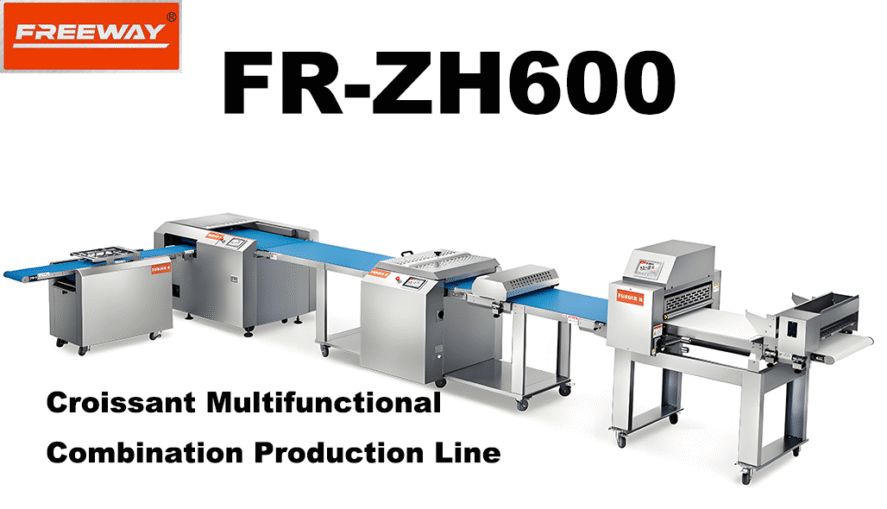

FR-ZH600 Croissant Multi-Combinataion Moulage de la ligne de moulage

fr-zh600-croissant-ligne-de-moulage-multi-combinaison

Penser aux machines et équipements de boulangerie? Pensez à l'autoroute!

Convient aux boulangeries, restaurants, hôtels, et autre entreprise de services alimentaires. La ligne de moulage multi-combinaison de croissants FR-ZH600 de Freeway est dédiée à la formation de tous types de croissants et de produits de boulangerie en bobines. Équipé de servomoteurs, caractéristiques de sécurité, Ordinateur micro-emballé, et panneau de touche LCD, Cette ligne augmente la production et l'efficacité de votre boulangerie. Sûr à utiliser et facile à nettoyer.

Toute la ligne se compose de 6 modules: Tête d'étalonnage, Séparatrice de feuilles de pâte, Outils de poinçonnage, Convoyeur et positionneur de plaques de cuisson, Unité d'enroulement de pâtons, et unité de contrôle de ligne.

je. Tête d'étalonnage

Le contrôle de la boucle de pâte garantit que la feuille de pâte passe à travers les multi-rouleaux sans tension ni étirement. (dans l'alimentation avec une échelle de pâte électromagnétique et à la sortie avec capteur de lumière).

- Traitement continu sans interruption

Ii. Séparatrice de feuilles de pâte

Une fois la feuille de pâte calibrée et passer à la diviseuse de feuilles de pâte, la pâte est découpée en bandes à travers un jeu de disques à découper.

III. Outils de poinçonnage

Cela garantit un haut niveau de précision en termes de forme, position et poids. Les outils sont faciles et pratiques à retirer et à remplacer en quelques étapes.

Iv. Convoyeur et positionneur de plaques de cuisson

V. Unité d'enroulement de pâtons

Pour assurer un enroulement uniforme et continu des pâtons, cette unité intègre un support d'enroulement et des courroies réglables de manière flexible, un rouleau presseur entraîné par servomoteur, et une ventouse sous vide qui fixe les pâtons à la ceinture. Les opérateurs peuvent régler de manière flexible l'écartement des rouleaux (qui contrôle le nombre de bobines) et sélectionnez les courroies d'enroulement (qui déterminent le type d'enroulement).

VI. Unité de commande de ligne

Nous utilisons un ordinateur micro-industriel à l'intérieur et installons un écran tactile LCD sur la surface de l'armoire pour former l'unité de contrôle de ligne. Interface graphique conviviale et concise. (Interface utilisateur graphique) joue un rôle important dans la surveillance, Réglage et interaction avec la ligne. C'est pourquoi nous avons développé le système d'exploitation intégré spécifique qui peut recevoir des paramètres de production (vitesse, longueur de coupe, type de remplissage et décalage de remplissage, mode de fonctionnement, etc.) entré par les utilisateurs du panneau LCD Touch. L'ensemble du processus de production est sous le toucher de vos doigts. L'écran tactile LCD peut ajuster en continu tous les entraînements par courroie.

Nous utilisons un ordinateur micro-industriel à l'intérieur et installons un écran tactile LCD sur la surface de l'armoire pour former l'unité de contrôle de ligne. Interface graphique conviviale et concise. (Interface utilisateur graphique) joue un rôle important dans la surveillance, Réglage et interaction avec la ligne. C'est pourquoi nous avons développé le système d'exploitation intégré spécifique qui peut recevoir des paramètres de production (vitesse, longueur de coupe, type de remplissage et décalage de remplissage, mode de fonctionnement, etc.) entré par les utilisateurs du panneau LCD Touch. L'ensemble du processus de production est sous le toucher de vos doigts. L'écran tactile LCD peut ajuster en continu tous les entraînements par courroie.

- Running simple et direct de la ligne

- Moniteur clair du processus de production

- Améliorer les performances de la ligne, robustesse, et stabilité

autoroute

autoroute

WeChat

Scannez le QR Code avec WeChat