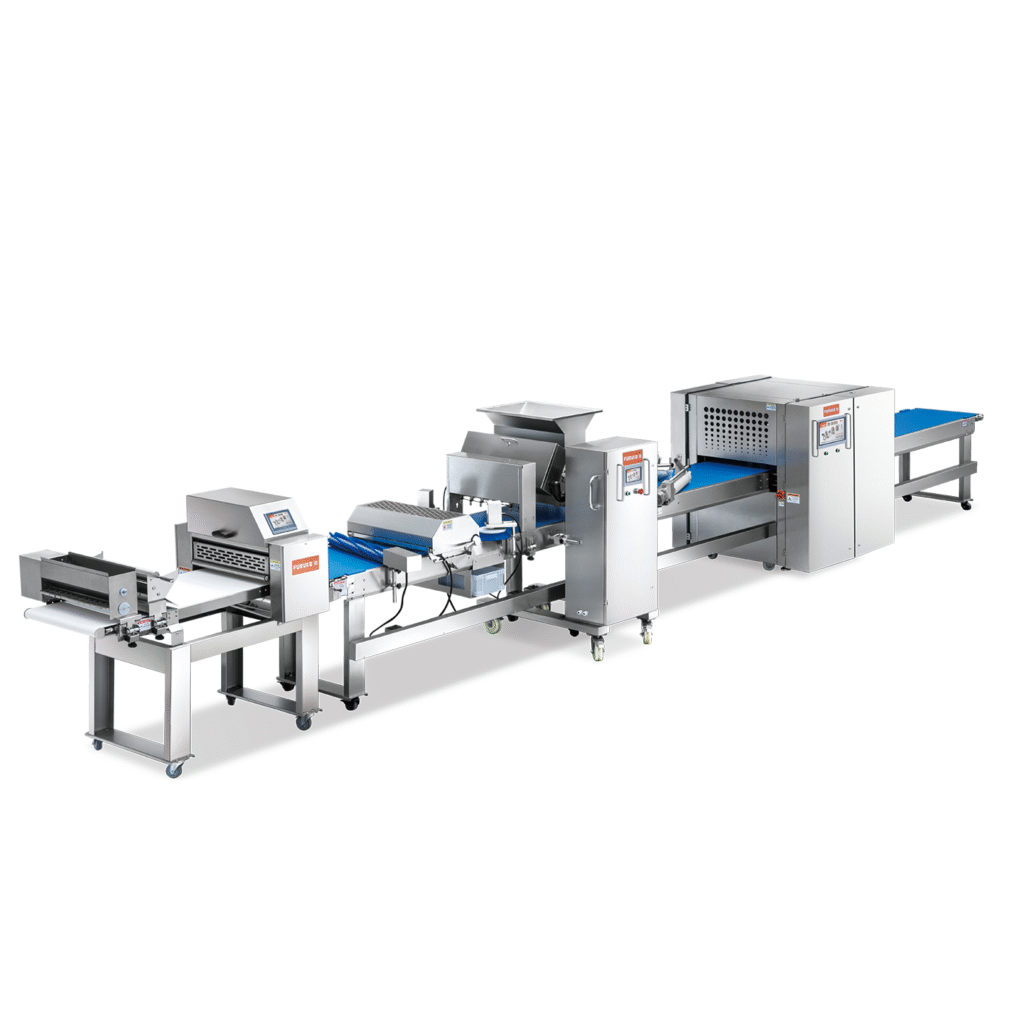

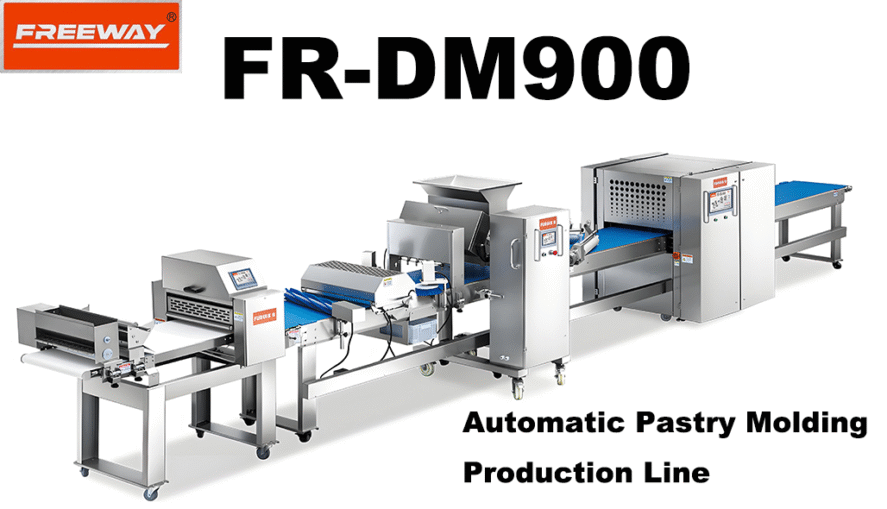

FR-DM900 High-efficient Pastry Production Line

FR-DM900 High-efficient Pastry Production Line

Thinking of bakery machinery and equipment? Think Freeway!

Suitable for bakeries, restaurants, hotels, and other foodservice company. Freeway’s FR-DM900 pastry make-up line is designed for optimal performance. Equipped with safety features, preset roller thickness controls, and foldable tables for space saving storage, this line increases your bakery’s production and efficiency. Safe to operate and easy to clean.

The whole line consists of 7 modules: 1. Calibrating head, 2. Embossing and screen unit, 3. Filling unit, 4. Coiling rollers, 5. Guillotine and punching tools, 6. Folding ploughs, 7. Line control unit.

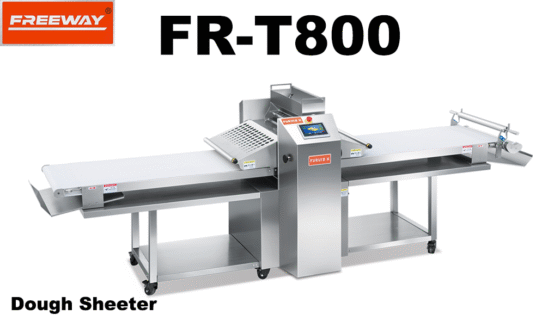

I. Calibrating head

When feeding the line with a dough spool, the calibrating head makes the thickcness and weight of the dough sheet (especially during transition) be uniformly distributed. The dough loop control ensures that the dough sheet passes through the calibrating head without tension or stretching (in the infeed with electromagnetic dough scale and at the outfeed with photoelectric sensor).

- Continuous processing without interruption

II. Embossing and screen unit

Embossing and screen unit

III. Filling unit

The filling unit can fill the dough sheet with uniformity and precision, without interruption.There are intake rollers inside the filling unit which are used for filling matters with limited flowability.A large variety of filling nozzles and application systems satisfies every possible requirement.

- Precise dosing and positioning of the filling

- Filling quantity is adjustable

- Quick and easy cleaning

IV. Coiling rollers

The coiling rollers enable automated, precise production of Danish whirls and similar products.

V. Guillotine and punching tools

The servo motor-driven guillotine works smoothly and slices accurately with electronic cutting length control. It achieves a performance of max. It is easy and fast to replace various blades and tools using the quick-change system and the positioning aid.

- Precise cutting and punching

- High capacity and flexibility

- Short transition time in replacing tools

VI. Folding ploughs

Reliable, individualized folding ploughs greatly facilitate the automated production of different pastries.

VII. Line control unit

The Line control unit is comprised of a micro-industrial computer inside and a LCD touch panel on the metal surface. User-friendly and concise GUI (Graphic User Interface) plays a significant role in monitoring, setting and interaction with the line. That’s why we have developed the specific embedded Operating Sysem which can receive production parameters (speed, cutting length, filling type and filling offset, operating mode, etc.) entered by users from the LCD touch panel. The whole production process is under the touch of your fingers. All belt drives can be continuously adjusted via the LCD touch panel.

- Simple and direct running of the line

- Clear monitor of the production process

- Enhance line performance, robustness, and stability1

freeway

freeway

WeChat

Scan the QR Code with wechat