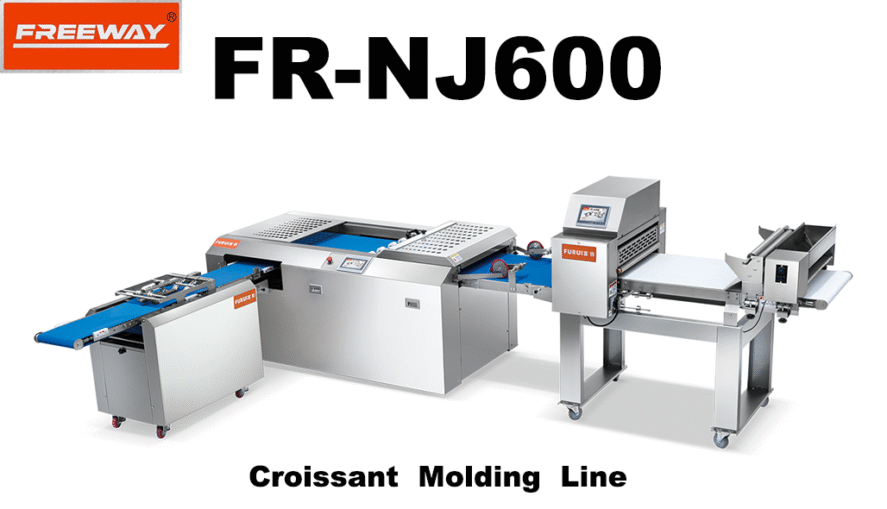

FR-NJ600 Croissant Molding Line

FR-NJ600 Croissant Molding Line

Thinking of bakery machinery and equipment? Think Freeway!

Suitable for bakeries, restaurants, hotels, and other foodservice company. Freeway’s FR-ZH600 croissant multi-combination molding line is dedicated to the formation of all types of croissants and coiled baking products. Equipped with servo motors, safety features, micro-embedeed computer, and LCD touch panel, this line increases your bakery’s production and efficiency. Safe to operate and easy to clean.

The whole line consists of 6 modules: Calibrating head, Dough sheet splitter, Punching tools, Baking tray conveyor and positioner, Dough pieces coiling unit, and Line control unit.

I. Calibrating head

The dough loop control ensures that the dough sheet passes through the multi-rollers without tension or stretching (in the infeed with electromagnetic dough scale and at the outfeed with light sensor).

- Continuous processing without interruption

II. Dough sheet splitter

Once the dough sheet has been calibrated and pass on to the dough sheet splitter, the dough is cut in stripes through a set of cutting discs.

III. Punching tools

This ensures a high level of accuracy in terms of shape, position and weight. The tools are easy and convenient to be removed and replaced with a few steps.

IV. Baking tray conveyor and positioner

V. Dough pieces coiling unit

To ensure uniform and continuous coiling of dough pieces, this unit integrates a flexibly adjustable coiling rack and belts, a servo-motor-driven pressing roller, and an underlying vacuum sucker that secures the dough pieces to the belt. Operators can flexibly set the roller gap (which controls the number of coils) and select coiling belts (which determine the coiling type).

VI. Line control unit

We use a micro-industrial computer inside and install a LCD touch panel on the cabinet surface to form the Line control unit.User-friendly and concise GUI (Graphic User Interface) plays a significant role in monitoring, setting and interaction with the line. That’s why we have developed the specific embedded Operating Sysem which can receive production parameters (speed, cutting length, filling type and filling offset, operating mode, etc.) entered by users from the LCD touch panel. The whole production process is under the touch of your fingers. The LCD touch panel can continuously adjust all belt drives.

We use a micro-industrial computer inside and install a LCD touch panel on the cabinet surface to form the Line control unit.User-friendly and concise GUI (Graphic User Interface) plays a significant role in monitoring, setting and interaction with the line. That’s why we have developed the specific embedded Operating Sysem which can receive production parameters (speed, cutting length, filling type and filling offset, operating mode, etc.) entered by users from the LCD touch panel. The whole production process is under the touch of your fingers. The LCD touch panel can continuously adjust all belt drives.

- Simple and direct running of the line

- Clear monitor of the production process

- Enhance line performance, robustness, and stability

freeway

freeway

WeChat

Scan the QR Code with wechat