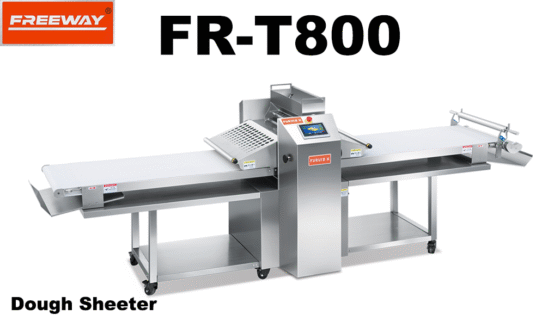

FR-T700 Dough Sheeter installed with micro-embedded computer and LCD touch panel which provides user-friendly interaction tools that makes it easy to be operated.

If you only make one batch for one loaf, we recommend using the dough roller rather than the dough hook. Additionally, the dough roller is also the preferred option when making doughs with a high liquid content or a lot of butter. Furthermore, it is very useful when baking gluten-free.

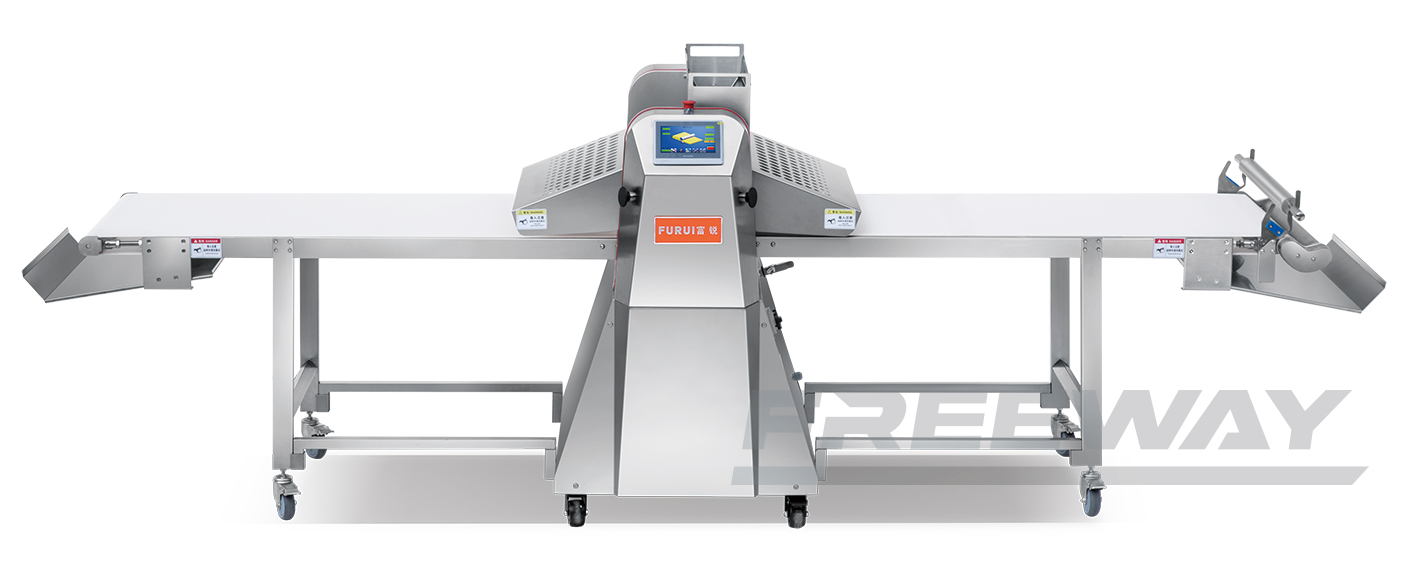

A high-quality sheeter produces a smoother, more consistent dough sheet compared to manual rolling.In fact, the dough will pass through at least one gauging roller or a conveyor, which in turn will reduce it to the right thickness.

freeway

freeway

WeChat

Scan the QR Code with wechat