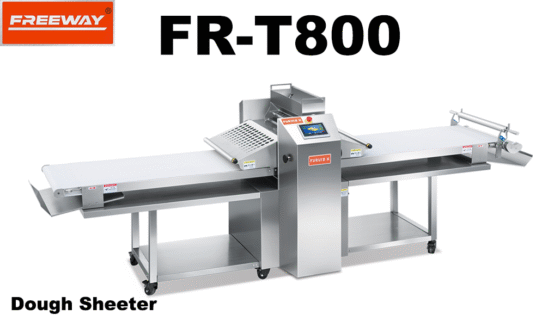

Dough-sheeterfoldablemini installed with micro-embedded computer and LCD touch panel which provides user-friendly interaction tools that makes it easy to be operated.

Ia maiti ana'e te taata faaohipa i te hoê faanahoraa taa ê e a tapea i te taviri haamata, E ohipa noa te rave'a ia au i te mau faataaraa no te omuaraa.

Te vai ra te mau rave'a aravihi roa o te nehenehe e ite i te tauiraa i te pae tino o te rahi o te api e te mau hape i roto i te millimeter.

Te auraa o te faaohiparaa i teie matini, o te hoê ïa hororaa rahi i mua i te aravihi e te tano i roto i te hamaniraa rahi.

Core Functions

- Layer Formation

- Precision Control

- Efficiency in Mass Production

- Bakery Products: Essential for making croissants, puff pastries, Danishes, and layered breads, where flakiness and texture are key.

- Pastry Shops: Used to prepare base doughs for tarts, turnovers, and other layered desserts, ensuring uniform layers that bake evenly.

- Industrial Production Lines

- Adjustable Lamination Cycles

- Temperature Regulation

- User-Friendly Operation

- Durable Construction

mā'ohio

mā'ohio

WeChat

A taui i te Ture QR e te wechat