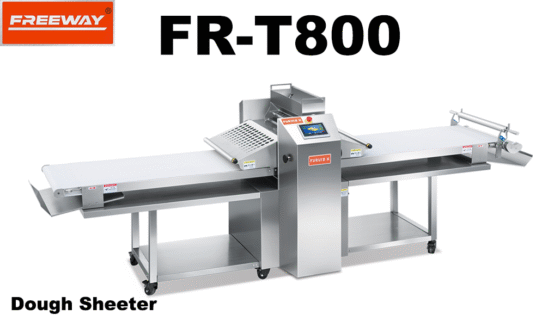

Dough-sheeterfoldablemini installed with micro-embedded computer and LCD touch panel which provides user-friendly interaction tools that makes it easy to be operated.

Sobald der Benutzer ein bestimmtes Produktprogramm auswählt und Starttaste drücken, Die Maschine funktioniert automatisch gemäß den Vorabstiegsparametern.

Es gibt hochempfindliche Sensoren, die die physikalische Änderung der Teigblechgröße mit Fehlerbereich in Millimeter erkennen können.

Die Anwendung dieser Maschinerie bedeutet große Vorwärtsverschiebung und Genauigkeit in der Massenproduktion.

Kernfunktionen

- Layer Formation

- Präzisionskontrolle

- Efficiency in Mass Production

- Bakery Products: Essential for making croissants, puff pastries, Danishes, and layered breads, where flakiness and texture are key.

- Pastry Shops: Used to prepare base doughs for tarts, turnovers, and other layered desserts, ensuring uniform layers that bake evenly.

- Industrial Production Lines

- Adjustable Lamination Cycles

- Temperature Regulation

- User-Friendly Operation

- Durable Construction

Autobahn

Autobahn

WeChat

Scan the QR Code with wechat