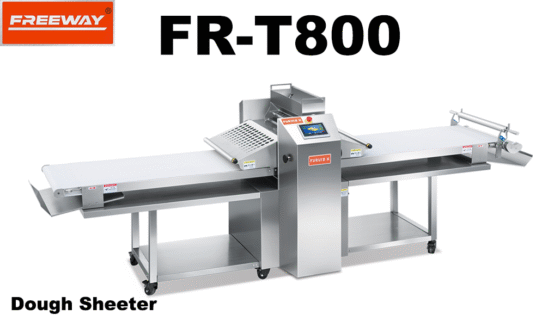

Dough-sheeterfoldablemini installed with micro-embedded computer and LCD touch panel which provides user-friendly interaction tools that makes it easy to be operated.

Once the user selects a specific product program and press start button, the machine will automatically work in accordance with pre-setting parameters.

There are highly-sensitive sensors which can detect the physical change of the dough sheet size with error range in millimeter.

Applying this machinery means great leap forward of efficiency and accuracy in mass production.

Core Functions

- Layer Formation

- Precision Control

- Efficiency in Mass Production

- Bakery Products: Essential for making croissants, puff pastries, Danishes, and layered breads, where flakiness and texture are key.

- Pastry Shops: Used to prepare base doughs for tarts, turnovers, and other layered desserts, ensuring uniform layers that bake evenly.

- Industrial Production Lines

- Adjustable Lamination Cycles

- Temperature Regulation

- User-Friendly Operation

- Durable Construction

高速道路

高速道路

微信

wechatでQRコードをスキャンしてください